Gravity Sewer vs. Pressure Sewer: Choosing the Right System for Your Community

Planning sewer infrastructure isn’t the most exciting part of development, but getting it wrong can be expensive. The choice between gravity and pressure sewer systems will impact your project for decades, from what you spend upfront to how much maintenance crews will be dealing with down the road.

Understanding the Basics

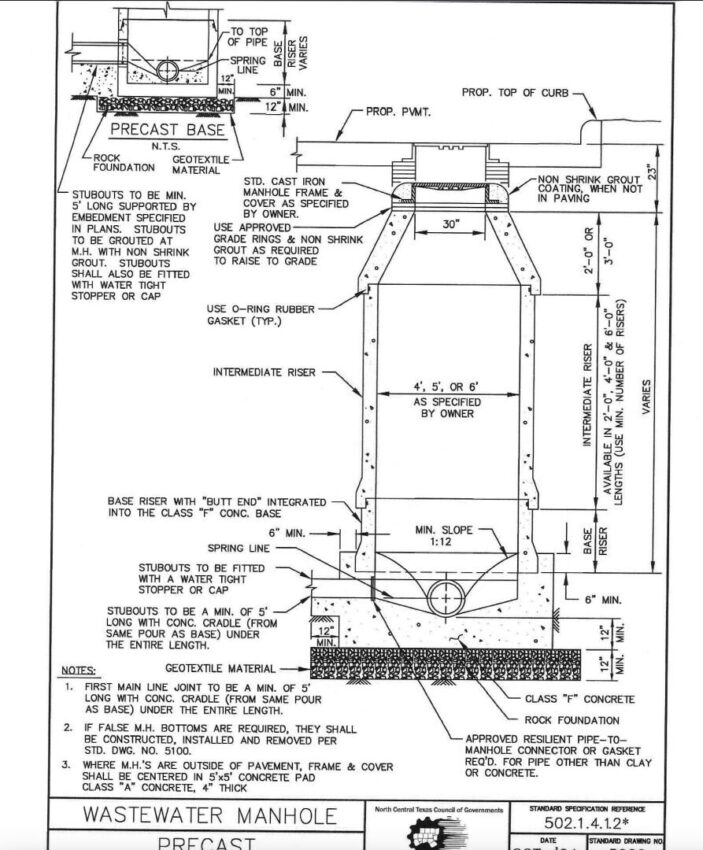

Gravity sewers do exactly what you’d expect. They use gravity to move wastewater downhill through pipes to treatment plants. Think of water flowing down a mountain stream. These systems need pipes installed at the right slope to keep everything moving in the right direction.

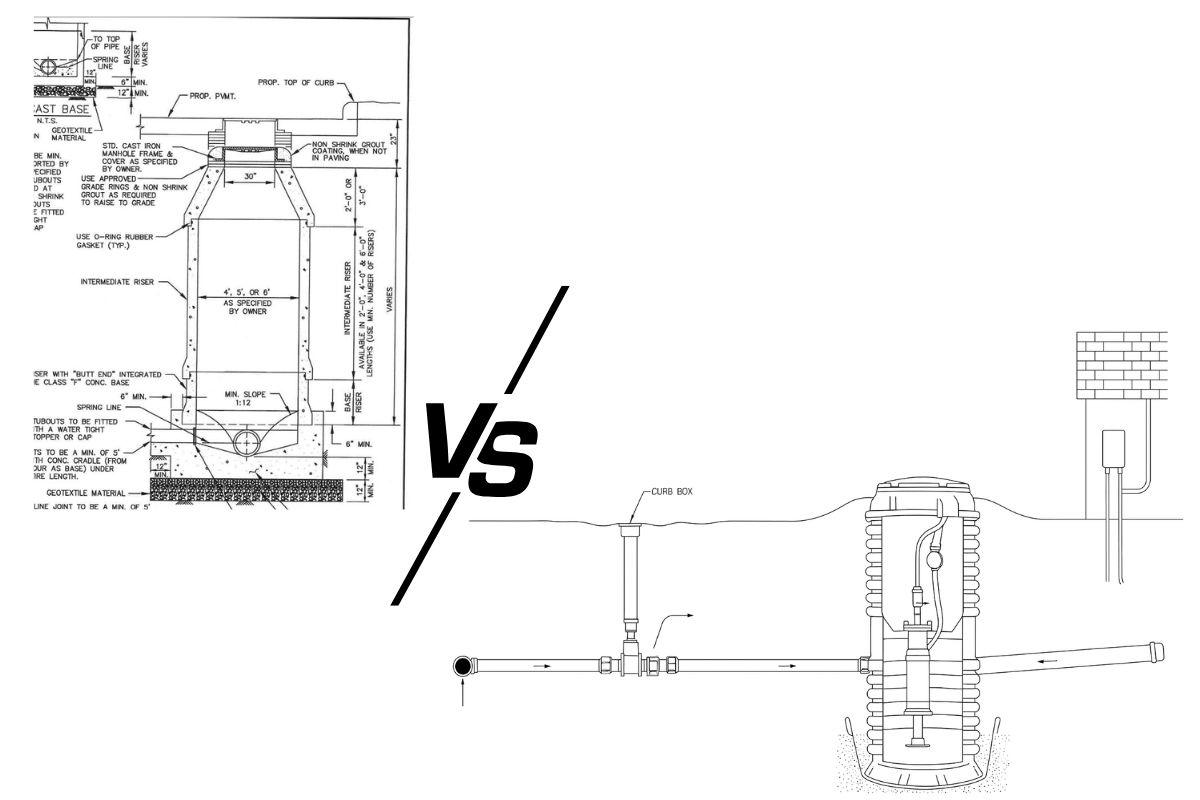

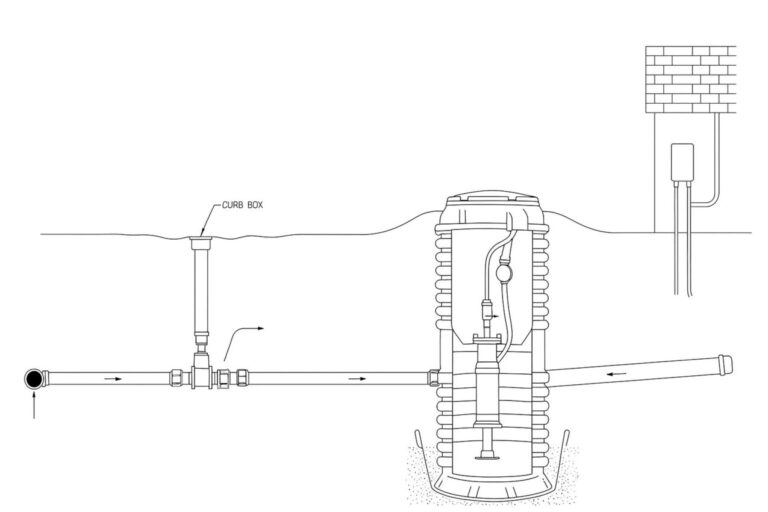

Pressure sewers work differently. They use pumps to push wastewater through smaller pipes under pressure. Each user connects to a pump that forces sewage through the collection system to treatment. Both get the job done, but which one makes sense depends on your specific situation.

Why Gravity Systems Work Well

Most engineers reach for gravity systems first, especially when the terrain cooperates. The natural slope does the work for you. If your community sits on a hillside that naturally flows toward where you want to put the treatment plant, gravity systems are often the obvious choice. No pumps needed, just proper pipe sizing and slope.

You’ll save money over time with gravity systems. Once these systems are in the ground, they basically run themselves. No electrical bills for pumping, fewer mechanical parts to break down. Maintenance crews know them inside and out because gravity systems have been around forever. Every public works department has dealt with them, so finding people to maintain and repair them isn’t a problem.

Gravity systems handle big flows easily. Large communities or areas expecting growth benefit from these systems because big pipes can carry lots of wastewater without breaking a sweat. The downside comes when you don’t have natural slope. Then you’re looking at deep trenches or lift stations to make gravity work, which can get expensive quickly.

When Pressure Makes More Sense

Pressure systems solve problems that would make gravity systems expensive or impossible. Challenging terrain is where pressure systems shine. Colorado has plenty of flat areas and places where you’d need to pump uphill to reach treatment facilities.

Installation is often easier with pressure systems. Smaller pipes mean less pipe costs. Also since the depth doesn’t matter you can bury the pipes at the minimum local bury depth, typical governed by frost depth. Anyone who’s tried to dig through Colorado hardpan or hit bedrock at six feet knows this matters. Pressure systems also offer routing flexibility that gravity can’t match. Pressure pipes can snake around obstacles, follow roads, and take the path of least resistance instead of fighting for the perfect slope.

What Goes Into the Design

Gravity systems need proper slope, usually 1-2% minimum depending on pipe size. You need adequate pipe depth for flow and manholes every so often for access and maintenance. You might need lift stations if the terrain won’t cooperate with natural flow.

Pressure systems require pump stations, either individual ones for each building or shared stations serving multiple connections. The pipes must be rated for pressure, and you need air release valves at high points in the system. Backup power systems are essential because when the pumps stop, the system stops working.

Your site conditions usually point you toward one system or the other pretty quickly. Engineers look at topography, soil conditions, and community needs to determine which approach makes the most sense.

The Money Question

Upfront costs vary depending on your site. Gravity systems cost more initially if you’re dealing with deep excavation or rocky conditions. Pressure systems have pump equipment costs but often easier installation, especially in challenging soil conditions.

Operating costs tell a different story. Gravity systems typically cost less to run since they don’t need electricity for daily operation. Pressure systems require power and regular maintenance of pumps and controls. This ongoing cost difference adds up over the decades your sewer system will be operating.

Maintenance is ongoing for both systems, but gravity systems generally need less attention once they’re working properly. Pressure systems have mechanical components that wear out and need replacement on regular schedules.

Colorado Considerations

Several factors matter specifically here in Colorado. Winter weather affects both systems. They need proper burial depth and freeze protection, though pressure systems sometimes have an edge in extremely cold areas because moving water doesn’t freeze as easily as standing water.

Soil conditions across Colorado can be challenging. We’ve got some tough digging in parts of the state. Rocky soils often favor pressure systems since you don’t need to go as deep. The Colorado Department of Public Health and Environment has requirements that both systems can meet with proper design.

Mountain communities face unique challenges with steep terrain, access issues, and seasonal population swings that affect system sizing. These factors often influence which type of system works best for a particular location.

Making Your Decision

Several factors should drive your choice. Look at your topography first. Natural downhill slope toward treatment makes gravity attractive. Flat ground or uphill runs point toward pressure systems.

Consider your soil conditions carefully. If you’re going to hit rock or hardpan, pressure systems’ shallower installation often saves money and construction headaches. Think about community size and growth patterns. Larger communities usually benefit from gravity systems’ capacity advantages.

Don’t forget maintenance capabilities. Make sure your community can properly maintain whatever system you install. Having qualified maintenance staff or contractors available makes a big difference in long-term system performance.

Getting Expert Help

This isn’t a decision to make with a coin flip. Experienced engineers evaluate all these factors together. They look at topography, soils, community needs, regulations, and costs to recommend the right system for your specific situation.

At Modern Engineering Solutions, we’ve designed both types of systems across Colorado. We know the local conditions, understand CDPHE requirements, and can help you make the choice that works best for your community or development. Whether you need feasibility studies, complete design, or help with permitting, we’ve got the experience to keep your project moving forward.

The sewer system you choose today will serve your community for generations. Getting it right from the start saves headaches and money down the road. Contact us at Sales@mod-eng.com, or call (720) 477-6565.