Guide to Design a Wastewater Treatment Plant in AutoCAD

Introduction

Designing a wastewater treatment plant layout requires both engineering insight and careful CAD drafting. This guide provides a step-by-step approach to creating an AutoCAD wastewater treatment plant design that is accurate, organized, and optimized for collaboration. Tailored as a civil engineering AutoCAD guide for city officials, district managers, professional engineers, municipal planners, and AutoCAD designers, the content focuses on conventional activated sludge systems. We’ll cover everything from initial preparation (gathering site plans and survey data) to detailed layout of treatment units, plus AutoCAD plant design tips on layer management, blocks, Xrefs, and leveraging new software features. If you’ve ever wondered how to draw a wastewater treatment plant in AutoCAD efficiently, read on – this guide will walk you through the process in a professional yet approachable tone.

Preparation: Gather Site Plans, Surveys, and Design Specs

Before diving into drafting, ensure you have all essential references on hand: Before diving into design, gather your site data and set up AutoCAD for success:

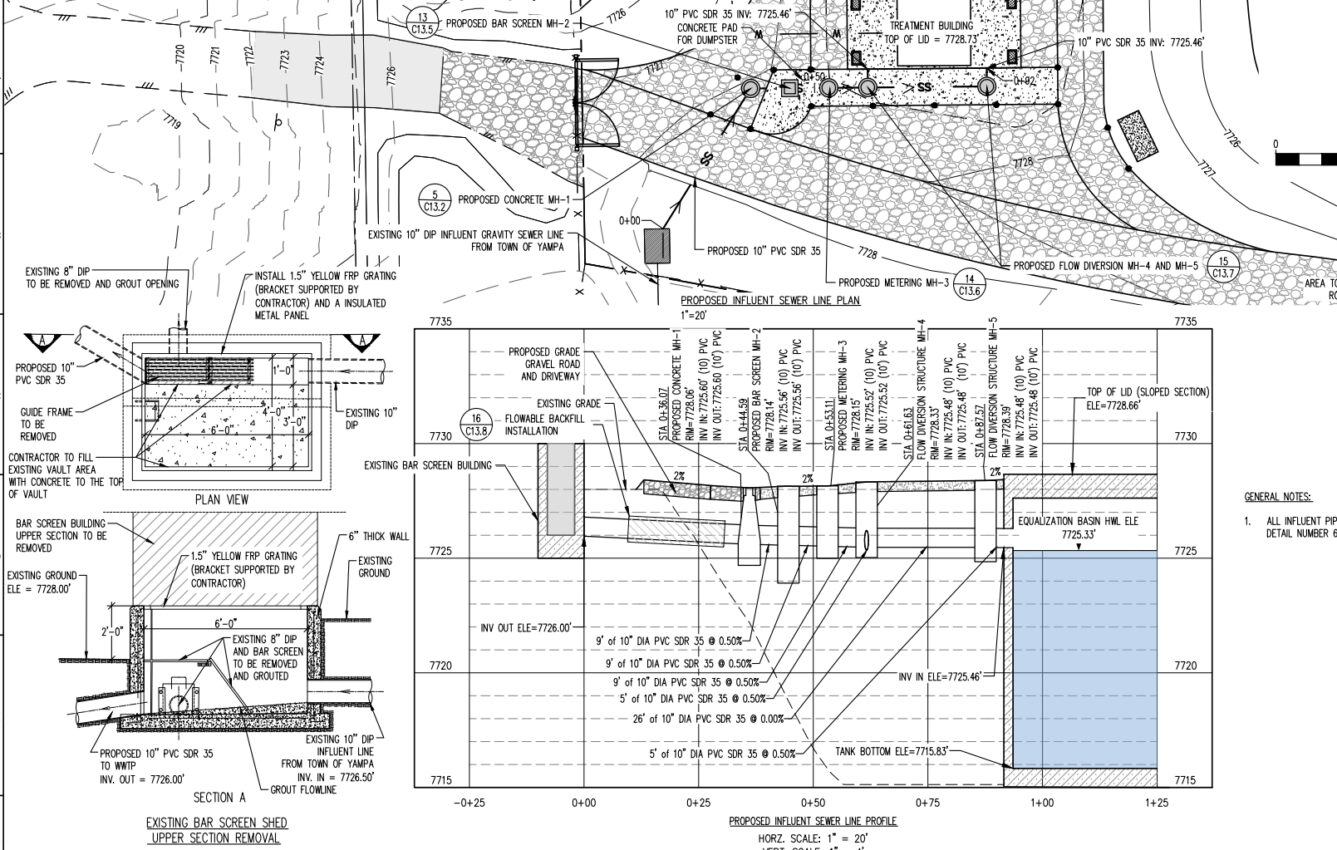

Import Accurate Survey Data: Start by attaching the site survey as an external reference (Xref) in AutoCAD. Ensure the drawing uses the correct units (typically feet in Colorado) and coordinate system. Bringing in surveyed points, topographic contours, and property boundaries as a base will ground your design in reality. For example, in Yampa’s project, a detailed survey ensured the new facility fit the site and avoided flood-prone areas.

Establish Project Specifications: Set up your drawing template with the project’s layers, text styles, and dimension styles per your standards. Include notes from the project specs (e.g. setback requirements, elevations, discharge point) early on. This preparation helps you adhere to municipal plant AutoCAD design criteria from the beginning.

Create Reference Geometry: Draw key reference lines such as property limits, easements, and existing utility locations on separate layers. This makes it easy to see constraints when laying out the treatment units. A well-prepared site plan underlay speeds up the entire wastewater plant layout AutoCAD process by providing context for all design elements.

Layer Management and External References (Xrefs)

Organizing your drawing with layers and Xrefs is crucial for clarity, especially on complex municipal projects:

Use Logical Layer Naming: Separate major categories into layers – e.g., civil site work, structural elements, mechanical piping, electrical, and annotations each on their own layer group. Adopting a consistent naming convention (such as the National CAD Standard) can help differentiate systems. For instance, some designers use a “D” prefix for process design layers (D for “Process”), so layers like

D-RAWS-PIPEcould denote raw sewage piping andD-RAS-PIPEfor return activated sludge lines. Clear layer names ensure anyone reviewing the drawing can instantly distinguish a sludge line from a clean water line.Layer Properties for Clarity: Assign distinct colors or linetypes to different systems – for example, use dashed lines for buried pipes or a specific color for electrical conduits. Keep consistent layer settings (line weights, etc.) so that when the plan is printed, the treatment units and pipes are clearly visible. Layer filters or layer states in AutoCAD can be used to toggle views (e.g., show only civil vs. only mechanical) for easier editing.

External References for Collaboration: Break the project into multiple drawings and Xref them together. A common approach is to have a base site plan Xref (with survey and civil features) and separate Xrefs for mechanical process piping or structural details. This way, multiple team members can work in parallel – for example, one drafter updates the site grading while another refines the piping layout. Attach Xrefs as Overlay to prevent nested references from cluttering other drawings. By managing Xrefs and layers carefully, your AutoCAD drawing remains organized even as the design evolves. Don’t forget to periodically purge unused layers and Xrefs to keep the file lightweight and efficient.

Layout Tips for Major Treatment Units (Headworks, Aeration, Clarifiers, Sludge Systems)

Drafting the major components of a conventional activated sludge plant requires both engineering insight and CAD technique:

Headworks Placement: Begin at the plant’s starting point – the headworks (influent screening and grit removal). Position the headworks structure at the incoming sewer location to minimize inlet pipe runs. Allow space for maintenance access (e.g., a driveway for service trucks to remove screenings). In AutoCAD, use concrete pad outlines or equipment blocks to represent the screening unit and any grit chamber. Ensure this area is on a layer for structures and label it clearly (e.g., “Influent Screen”).

Aeration Basins: Next, lay out the aeration basin(s) downstream of the headworks. For a conventional activated sludge system, these basins are typically rectangular tanks. Draw the basin walls to scale using actual design dimensions (length, width, and water depth) provided by the process engineer. It’s wise to maintain symmetry and straight flow paths – place aeration basins such that flow can go by gravity to the clarifiers. In the Yampa WWTP design, the aeration basin was oriented to feed two secondary clarifiers by gravity, which simplified piping. Use hatches or fill to distinguish water areas, and consider adding text or a block indicating diffusers or aerators within the basin.

Secondary Clarifiers: Position the clarifier(s) immediately after the aeration basin. Often these are circular in plan. Use a circle or polygon of the correct diameter to represent the clarifier tank. If your clarifier is 40 feet in diameter, draw it exactly to scale – precise geometry ensures all piping fits later. Leave room around clarifiers for walkways and sludge pump stations. You might Xref in manufacturer drawings for the clarifier mechanism to get details like center pier or rake arms if needed, or simply represent them with centerlines and a note. Label each clarifier (e.g., “Secondary Clarifier No.1”) and denote the water flow inlet and effluent weir locations on your plan for clarity.

Sludge Handling Systems: Include space for sludge processing units. This could be an aerobic digester, sludge holding tank, or dewatering equipment depending on your design. For drafting, place sludge facilities near the clarifiers to shorten sludge piping (e.g., locate a sludge holding tank adjacent to clarifier effluent lines for easy waste activated sludge [WAS] withdrawal). Use rectangular or circular shapes as needed to show these units, and hatch or color-code them if it helps visualization. Also indicate where sludge will be hauled off or dried (a drying bed or truck loading area) – for instance, draw a driveway or pad for sludge removal. By planning these units’ locations early in AutoCAD, you ensure there’s no interference between structures and you have adequate clearance as per the specs (e.g., OSHA requires certain distances for safety around open tanks).

Each unit’s placement on the site plan should follow the process flow sequence. Align them in a logical order (often a straight line or U-shape flow) to make the wastewater plant layout easy to understand. Remember to check setbacks and prevailing winds – e.g., place odor-generating units like headworks downwind from offices or neighbors when possible. These practical layout decisions, translated into CAD, result in a functional and regulatory-compliant Colorado wastewater treatment design.

Piping Layout and Indicating Flow Direction

With major structures in place, the next step is connecting them with piping and channels:

Draw Pipes to Scale: Use AutoCAD polylines or pipes drawn as lines to connect each process unit in the flow order (influent sewer to headworks, headworks to aeration, aeration to clarifier, etc.). Draw pipe centerlines with correct alignment and include bends/manholes where required. It’s important to reflect real distances so that you can later verify slopes for gravity pipes if needed. Consider using different linetypes for different pipe purposes: e.g., a dashed line for subsurface gravity sewer lines, a solid line for pressurized sludge return lines. Keep piping on a dedicated “piping” layer group for clarity (you might have sub-layers like

PIPE-RAW,PIPE-RAS, etc.).Annotate Pipe Sizes and Slopes: Clearly label each pipe with diameter and material (e.g., “12″ PVC”) and, for gravity lines, note the slope or invert elevations if known. This information is crucial for operators and engineers reviewing the plan. AutoCAD’s annotation tools or dynamic blocks can help create consistent labels. For example, you might have a block with an arrow and text for “Flow 12″ Ø” that you reuse.

Indicate Flow Direction: Always show the direction of flow along pipes and open channels. This can be done by adding arrow symbols or using a flow arrow linetype. For simplicity, you can block-in an arrowhead and copy it along the pipe, or use the Multileader tool with an arrow style pointing in the flow direction. In a complex AutoCAD wastewater treatment plant drawing, these flow arrows guide the reader through the process, from influent to effluent. Make sure every major line (influent sewer, effluent outfall, sludge recycle, etc.) has a flow direction indicated.

Avoid Clutter and Crossing: Route pipes logically to minimize crossings on the plan. If pipes must cross, use AutoCAD’s drafting techniques to clarify – for instance, break the line and indicate one pipe goes under another with a note or using different line weights (a thinner line for the lower pipe). Keep adequate spacing between parallel pipelines to scale (e.g., if two 12-inch pipes run side by side, don’t draw them right on top of each other in CAD; separate them visually and note the spacing if needed). Good piping layout in AutoCAD will mirror good field installation practice, preventing confusion during construction.

Include Appurtenances: Mark the locations of key valves, pumps, and other appurtenances. You can use standardized blocks for valves, gate mechanisms, or pump symbols. For example, at the base of the clarifier, place a pump symbol on the RAS line indicating the return activated sludge pump station. Similarly, add a valve symbol where the effluent line can be controlled. Using blocks not only makes the plan clearer but also lets you leverage AutoCAD’s COUNT or data extraction features later to list equipment.

File Organization and Leveraging the Latest AutoCAD Features

A well-organized CAD file and using modern AutoCAD tools will save time and reduce errors:

Structured File and Xref Organization: Maintain a clean folder structure for your project. Keep Xref files (survey base, mechanical plan, electrical plans) in a consistent location relative to the main drawing. Use clear naming (e.g.,

Yampa_WWTP_Base.dwg,Yampa_WWTP_Piping.dwg, etc.) so team members know which file to open for each aspect. When it comes time to produce plan sets, consider using the Sheet Set Manager in AutoCAD to organize sheets, titles, and numbering automatically. This ensures that all drawing sheets (site plan, P&IDs, sections) stay coordinated.Utilize New AutoCAD Features: The latest AutoCAD release (AutoCAD 2025) offers enhanced tools that can be very useful for wastewater plant design drawings. For example, the Xref Compare feature allows you to see changes in an updated survey or architect’s drawing that you’ve Xrefed in – crucial when working with evolving site data. The Count tool can automatically count instances of blocks (helpful to verify you’ve placed all the valves or diffusers needed). Additionally, AutoCAD’s Trace and Share features enable cloud-based collaboration: team members in different offices (say, Golden and the project site in Yampa) can mark up the drawing without altering the original, speeding up review cycles.

Dynamic Blocks and Reusable Content: Leverage AutoCAD’s block libraries for common elements in a wastewater treatment plant. Create dynamic blocks for items like tanks, pumps, or manholes that allow you to adjust sizes or notes on the fly. This not only saves drafting time but keeps symbols consistent throughout the drawing set. For instance, a dynamic block for a clarifier could let you toggle diameters or add a label, rather than drawing each clarifier from scratch. Over time, building a library of these components tailored to municipal plant AutoCAD design needs will greatly improve efficiency.

Regular Quality Checks: Use built-in tools to keep the file healthy. Periodically run

AUDITandPURGEto clean up errors and unused items. Take advantage of layer standards and CAD standards checking if your firm has them, to ensure compliance with Colorado or client CAD standards. Set up page layouts with proper plot styles early on so that when you print the plan (whether full-size or half-size), the layers and colors yield a legible output. Little details like north arrows, scale bars, and title blocks should be included via Xref or blocks on every sheet for a professional result.

Conclusion

Drafting a wastewater treatment plant in AutoCAD is a manageable task when approached methodically. By preparing the site plan with accurate survey data and using well-structured layers and Xrefs, you create a strong foundation for your design. Thoughtful layout of process units – from headworks to clarifiers and sludge systems – ensures the wastewater plant layout is both functional and clear. Detailed piping drawings with flow directions and consistent annotations help communicate the design to stakeholders and construction teams. Finally, staying organized and utilizing the latest AutoCAD features streamlines the workflow and reduces errors.

Whether you’re designing a new facility for a small town like Yampa, CO or upgrading a larger municipal plant in Colorado, these AutoCAD drafting guidelines will help you produce a clean, professional drawing that meets regulatory standards and operational needs. With a well-drawn plan in hand, project teams can confidently move from design to construction, knowing the municipal wastewater treatment design has been accurately translated into the CAD drawings. Keep these tips handy for your next project, and happy drafting!