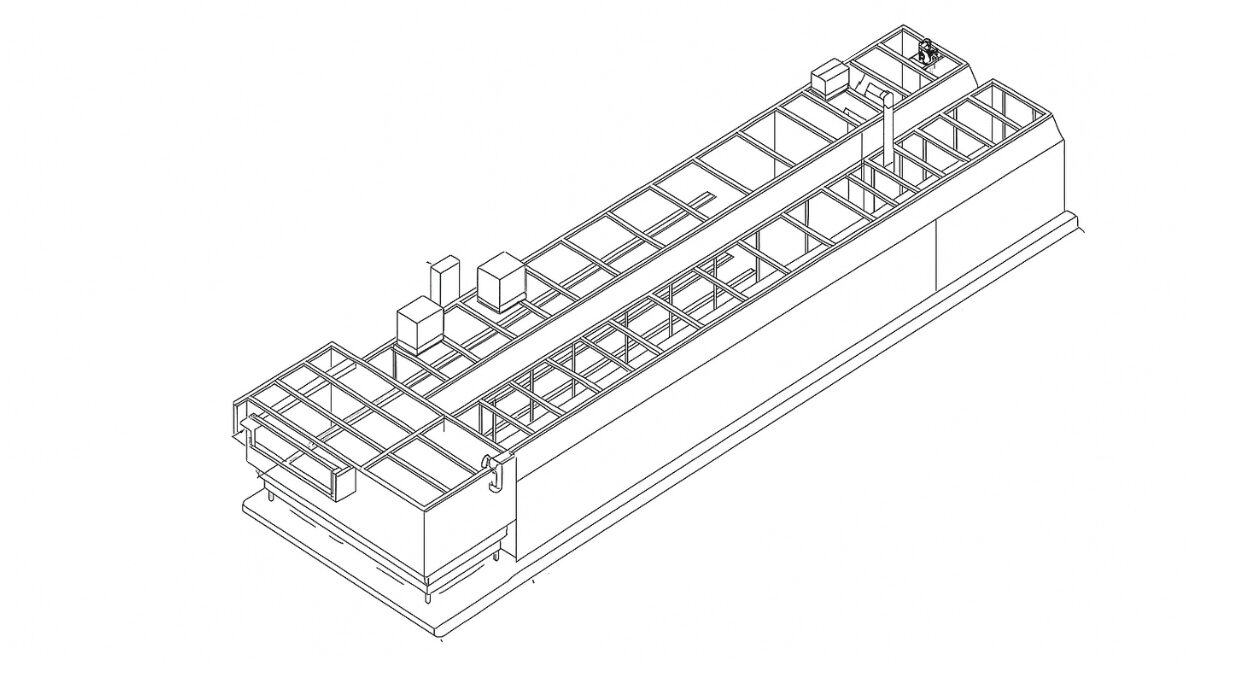

Package Wastewater Treatment Plant

Modern Engineering Solutions specializes in designing package (pre-engineered) wastewater treatment plants that serve 10,000 up to 5,000,000 gallons per day throughout Colorado. Our professional engineers create compact treatment systems using extended aeration, sequencing batch reactors, and membrane bioreactors to achieve effluent quality that meets or exceeds CDPHE standards. Each design accounts for site-specific challenges including high altitude oxygen transfer limitations, extreme temperature variations, and variable seasonal flows common in mountain communities.

Expert Package Plant Design Services

Our design process begins with comprehensive wastewater characterization and flow analysis, establishing peak factors and growth projections that size equipment properly for 20-year planning horizons. We calculate precise biological loading rates, oxygen requirements, and hydraulic retention times to ensure consistent BOD and TSS removal as low as 5 mg/L. For communities requiring nutrient removal, our designs incorporate anoxic zones and chemical feed systems achieving ammonia levels below 0.1 mg/L and total nitrogen below 5 mg/L.

Technical Design Excellence

Package plant design demands specialized expertise beyond conventional treatment engineering. Our team optimizes biological processes within confined steel tanks, carefully balancing mixed liquor concentrations, return activated sludge rates, and waste sludge quantities to maintain stable operation. We specify fine-bubble diffuser grids with dissolved oxygen control systems that reduce energy consumption by 30% compared to surface aerators while maintaining required oxygen transfer rates adjusted for Colorado’s elevations.

Hydraulic design receives particular attention in our package plants. We model flow patterns through each unit process, calculating headloss and ensuring adequate pump capacities for peak instantaneous flows. Our clarifier designs incorporate EDI baffles and scum removal systems that achieve excellent settling in circular tanks as small as 12 feet diameter. Every hydraulic calculation accounts for temperature impacts on viscosity and settling rates, critical for maintaining performance during Colorado’s cold winters.

Colorado-Specific Engineering Solutions

Designing package plants above 8,000 feet elevation requires fundamental adjustments to standard engineering practices. We increase blower capacities by 25-30% to compensate for reduced atmospheric pressure, specify deeper diffuser submergence to enhance oxygen transfer, and design biological systems for cold-weather operation down to -20°F. Our high-altitude designs include insulated steel tanks, enclosed blower buildings with heating systems, and heat-traced piping throughout.

Mountain communities face dramatic seasonal flow variations that challenge biological treatment stability. Our equalization basin designs buffer ski season peaks while maintaining minimum velocities preventing solids deposition during summer lows. We incorporate step-feed configurations allowing operators to adjust treatment capacity by bringing tankage online incrementally. These flexible designs handle 5:1 peak-to-average flow ratios without washing out biological mass or compromising effluent quality.

Regulatory Expertise and Permitting

Colorado’s regulatory framework requires careful navigation from conceptual design through construction approval. We prepare comprehensive engineering reports addressing CDPHE Regulation 22 requirements, demonstrating hydraulic capacity, organic loading compliance, and operational reliability. Our submittal packages include detailed calculations, manufacturer equipment data, and operational strategies that expedite state review.

We coordinate pre-application meetings with Water Quality Control Division engineers, establishing effluent limitations and monitoring requirements before finalizing designs. This proactive approach prevents costly redesigns and accelerates approval timelines. Our strong relationships with state reviewers, built through decades of successful projects, facilitate smooth permitting even for complex applications requiring antidegradation analyses or TMDL evaluations.

Construction Documentation and Support

Modern Engineering produces construction documents that translate professional treatment processes into buildable projects. Our plan sets include detailed process flow diagrams showing all piping and valving, equipment layout drawings with maintenance access clearances, and electrical schematics incorporating motor control centers and variable frequency drives. We specify each component from reputable manufacturers including Cloacina, Kobota, and Newterra ensuring competitive bidding while maintaining quality.

During construction, we provide responsive support addressing contractor questions within 24 hours. Our construction administration services include shop drawing review, startup assistance, and operator training. We remain involved through performance testing, ensuring your package plant achieves design parameters before accepting substantial completion. This comprehensive approach delivers operational facilities, not just approved drawings.

Modern Engineering Solutions – Your Package Plant Design Partner

Modern Engineering Solutions brings focused expertise to package wastewater treatment plant design. Our professional engineers have completed over 20 package plant designs ranging from small RV parks to growing municipalities. We maintain the technical depth to engineer sophisticated biological nutrient removal while keeping designs practical for communities with limited operations staff.

When Colorado communities need package wastewater treatment solutions, Modern Engineering Solutions provides the specialized expertise essential for success. Contact our professional engineers at (214) 633 6748 or Mike@mod-eng.com to discuss your specific project requirements and receive a detailed fee proposal within 48 hours.