Mechanical Wastewater Treatment: Simple Solutions for Solids Management

Welcome to another episode of “Engineers for Communities,“, where we delve into innovative solutions that impact rural communities, developers, and engineers.

This episode was filmed at WEFTEC 2023, and features insights from industry expert Simon Randle of Huber Technology. Simon highlights cutting-edge methods for mechanical solids separation and sludge dewatering. Huber develops performance guarantees based on the results of site-specific bench and pilot scale testing, ensuring compliance for clients from small rural towns to large municipal plants.

Let’s dive into the world of mechanical wastewater solutions!

Effective Screening Technology

One of the first steps in wastewater treatment is screening, which removes large solids from the water. Huber Technology’s screening systems are designed to handle high volumes of water efficiently. These screens use a rotating drum and rakes to separate solids from the water, which is then compacted and ready for disposal. This process helps protect pumps and other equipment from damage, ensuring the system runs smoothly.

Grit Wolf: High Tech Grit Removal System

Grit, like small stones and sand, can cause serious problems in wastewater treatment plants. It wears down pumps and clogs systems. Huber’s Grit Wolf system efficiently captures even the smallest particles, ensuring that the water treatment process is more efficient and less prone to breakdowns. Competitive advantages of the Grit Wolf include:

- Removes grit as small as 75 microns, much finer than traditional systems

- Screens are pulled up and pressure washed without taking the system out of service – No need for a secondary system.

Efficient Sludge Management Solutions

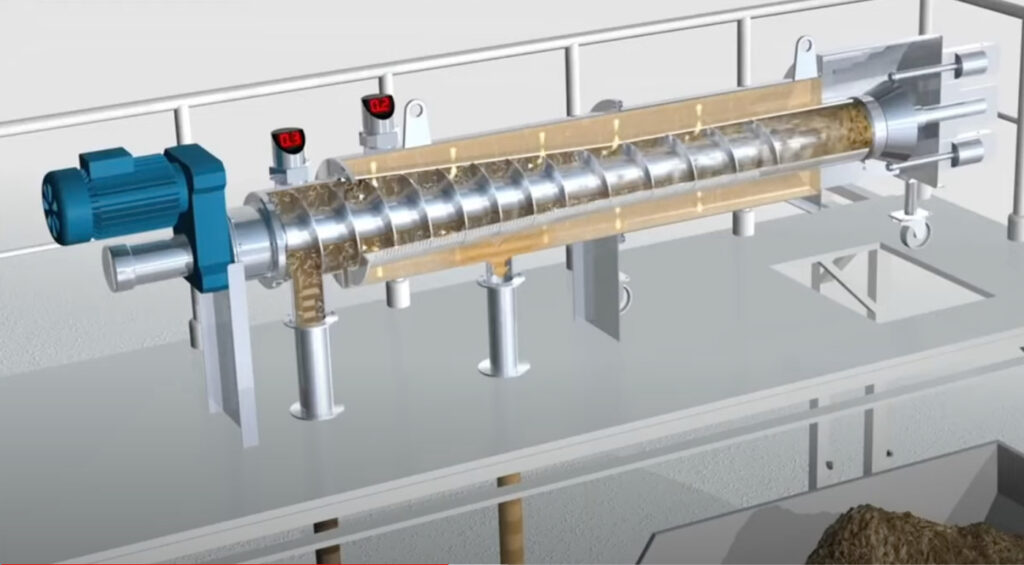

After wastewater is treated, what’s left is called sludge, a thick, muddy substance. Managing this sludge is crucial to keep costs down and reduce environmental impact. Huber Technology offers solutions like the strain press and screw press to remove unwanted materials from sludge and to dewater it, making it lighter and easier to transport. These processes significantly reduce the volume of sludge, cutting down on transportation and disposal costs.

Huber also provides ecofriendly drying solutions for sludge. In sunny areas, their solar drying systems use the sun’s energy to dry sludge, turn it into a powdery substance that is easy to handle. For areas that need a more intensive drying solution, Huber’s thermal dryers use hot air to ensure the sludge is 90% dry. This dried sludge can even be used as fertilizer, turning waste into a valuable resource.

Huber’s Approach for Developing Site Specific Performance Guarantees

Huber develops performance guarantees based on site-specific bench and pilot scale testing. Here’s how the process works:

- Bench Test: Determine the optimal type and quantity of polymer for dewatering using the site-specific wastewater. Pick a polymer type and dewatering process and make recommendations for the pilot test.

- Site Pilot: Huber will send a smaller version of the screw press, strain press or other dewatering technology on-site for a week to measure performance and adjust parameters.

- Final Report: Results of the site pilot are presented in a detailed report with specifications, performance results, and polymer usage.

- Final Specification and Performance Guarantees: Develop final machine specs and guarantees based on performance, aiming for optimal dry solids content.

The goal is to ensure that the solution can achieve the desired dry solids content, typically around 20 percent, acceptable for landfill disposal. For higher dry solids content, up to 90 percent, which reduces the sludge to almost a powder, larger investments in equipment are required. The decision to pursue such investments depends on factors like landfill rules and transportation distances, as some states have specific regulations, and transport costs vary significantly.

Local Manufacturing and Compliance

To better serve the U.S. and Canadian markets, Huber Technology is expanding its manufacturing capacity in Denver, North Carolina. This local production ensures that they can meet the requirements of the Build Back America Act and the Inflation Reduction Act, which support American-made products and sustainability. By manufacturing locally, Huber also reduces shipping costs and supports the local economy.

Conclusion

Huber Technology is making wastewater management easier and more efficient for communities and industries. Their advanced screening, grit removal, and sludge management solutions help protect the environment and reduce costs. With their commitment to innovation and sustainability, Huber Technology sets a high standard for the industry, showing that effective wastewater management is achievable with the right technology.

For more information about Huber Technology’s wastewater solutions, visit their website at https://www.huber-technology.com/.