Texas Water Infrastructure Crisis: $134 Billion Funding Gap

Texas needs $154 billion to fix its water infrastructure but committed only $20 billion. With 186 billion gallons lost annually and pipes dating to the 1890s, developers face serious project risks from aging municipal systems.

MUD Formation Costs Texas Developers $2.7M Before Breaking Ground: Faster Wastewater Alternatives Exist

Municipal Utility District formation consumes 18-24 months and significant capital before developers install a single pipe. For Texas development projects in extraterritorial jurisdiction areas requiring wastewater infrastructure, the traditional MUD pathway creates timeline risk that increasingly threatens project viability.

How to Access $2 Billion in Senate Bill 7 Funding for Texas Water Reuse Projects

Senate Bill 7 (SB7) makes $2 billion available for Texas water reuse and new water supply projects over the next 22 years.

How to Cut TCEQ Wastewater Permit Timeline from 12 Months to 6-8 Weeks Using Reuse Authorization

Most Texas developers accept 12-month TCEQ permitting timelines as unavoidable, building substantial carrying costs into every project pro forma. The reality: this timeline is not a regulatory requirement. Strategic permit selection, particularly reuse authorizations instead of traditional discharge permits, can reduce approval timelines to 6-8 weeks.

Land Application Permits for Treated Wastewater: A Texas Developer’s Guide

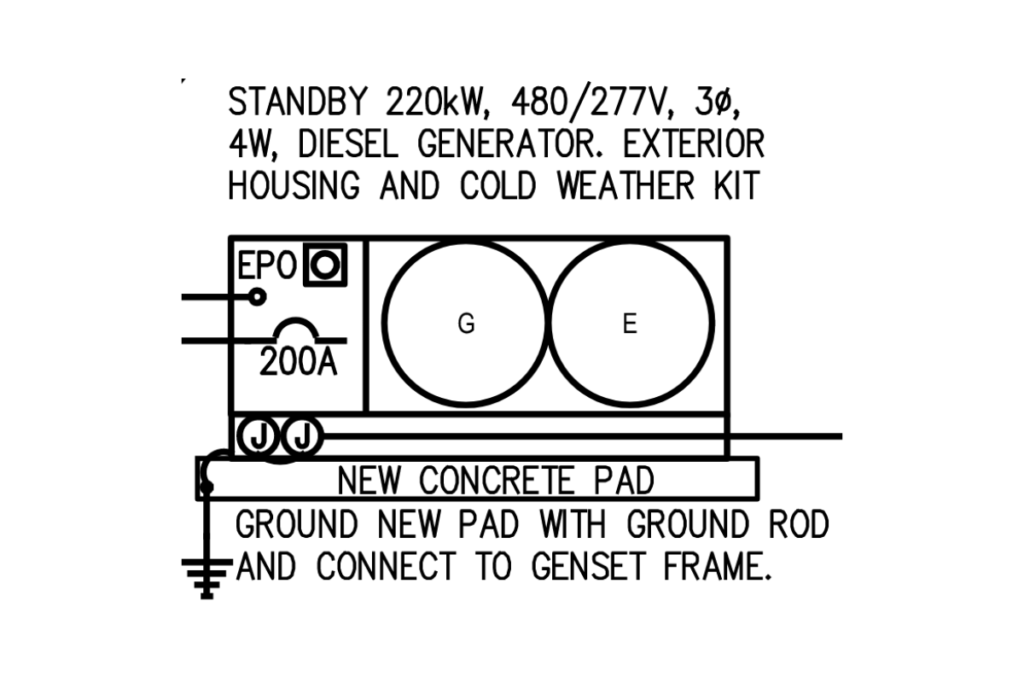

The Texas Commission on Environmental Quality (TCEQ) requires every regulated water and wastewater facility to demonstrate that essential systems will continue to operate during an electrical outage. This requirement is not just a formality; without backup power, a distribution system can lose pressure in a matter of minutes, disinfection can stop, and wastewater lift stations can overflow. Any of these conditions can create a direct public health hazard and, at the same time, put the utility in violation of its permit.

We Just Told a Client Their $15,000 Project Wasn’t Worth Our Time—They Thanked Me for It

The Texas Commission on Environmental Quality (TCEQ) requires every regulated water and wastewater facility to demonstrate that essential systems will continue to operate during an electrical outage. This requirement is not just a formality; without backup power, a distribution system can lose pressure in a matter of minutes, disinfection can stop, and wastewater lift stations can overflow. Any of these conditions can create a direct public health hazard and, at the same time, put the utility in violation of its permit.

TCEQ’s Power Reliability Requirements: Generator vs. Dual Feed Design

The Texas Commission on Environmental Quality (TCEQ) requires every regulated water and wastewater facility to demonstrate that essential systems will continue to operate during an electrical outage. This requirement is not just a formality; without backup power, a distribution system can lose pressure in a matter of minutes, disinfection can stop, and wastewater lift stations can overflow. Any of these conditions can create a direct public health hazard and, at the same time, put the utility in violation of its permit.

Reuse vs. Discharge: Which Wastewater Strategy Fits Your Texas Development?

Every Texas developer faces the same critical decision: discharge treated wastewater into streams or set up reuse for local farms and businesses. This choice impacts everything from permit timelines to project costs. Getting it wrong can destroy your timeline and budget.

Cloacina’s Integrated Wastewater Solutions: How Developer-Focused Design Creates Better Treatment Systems

Manholes collapsing in your community is one of those infrastructure nightmares that keeps public works directors up at night. When residents see emergency crews digging up streets and sewage backing up into their neighborhoods, they understandably demand answers. The truth is, most manhole failures come from predictable deterioration that we can prevent with the right approach. Understanding these problems helps communities fix them before they become expensive emergencies.

When Experience Isn’t Enough: Why Current Civil Engineering Standards Matter More Than Years of Practice

During a routine plan review for a California water infrastructure project last week, our team encountered something that made us pause. The cover sheet didn’t just have minor issues—it was fundamentally non-compliant with current California engineering standards.

These emergencies hit small Colorado communities particularly hard. Emergency repairs cost tens of thousands in contractor overtime and regulatory fines. Traditional solutions require upsizing collection systems or upgrading treatment plants that most communities can’t afford. The choice becomes impossible – face financial ruin or continue risking environmental disasters that bring state regulators to your door.

Real-Time Water Quality Monitoring Using Proteus Fluorescence Technology

In this episode, we engage with Michael Malone from Proteus, who provides comprehensive insights into advanced water quality monitoring solutions that transform environmental assessment and regulatory compliance. We explore how fluorescence-based sensor technology brings proven laboratory analysis capabilities directly to field applications, enabling real-time monitoring across diverse water systems. These innovations eliminate traditional sampling delays while providing continuous data streams essential for process control, regulatory reporting, and pollution source identification. Join us as we examine how Proteus technology addresses critical monitoring challenges facing municipal operators, environmental consultants, regulatory agencies, and industrial facility managers.

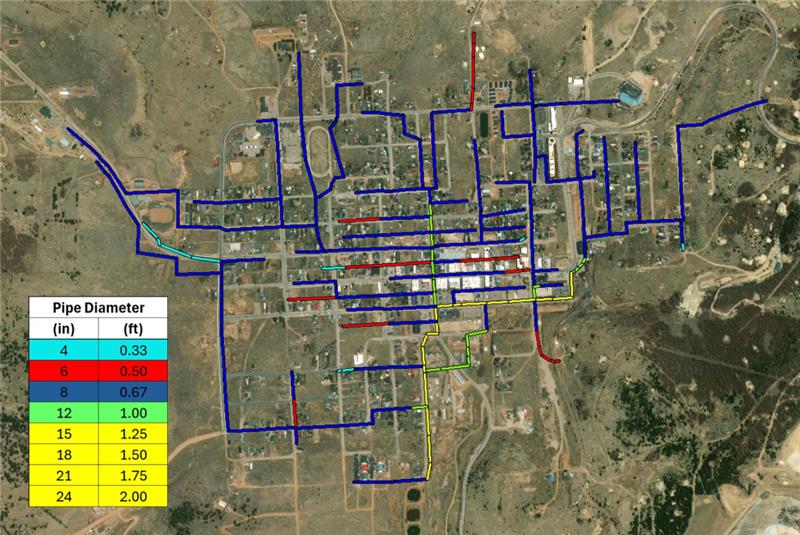

5 Common Wastewater Hydraulic Modeling Mistakes That Kill Project Budgets

Wastewater hydraulic modeling failures create some of the worst emergencies communities can face. Unlike water system problems that develop gradually, wastewater modeling mistakes reveal themselves during peak flow events when collection systems overflow into streets or treatment plants can’t handle incoming flows. Raw sewage backups trigger immediate environmental violations and can shut down entire developments within hours.

These emergencies hit small Colorado communities particularly hard. Emergency repairs cost tens of thousands in contractor overtime and regulatory fines. Traditional solutions require upsizing collection systems or upgrading treatment plants that most communities can’t afford. The choice becomes impossible – face financial ruin or continue risking environmental disasters that bring state regulators to your door.

How WaterOperator.org Solves Small Water System Crisis: Free Resources That Actually Work

In this episode of Engineers for Communities, we spoke with Steve Wilson from WaterOperator.org about tackling one of today’s most critical infrastructure challenges: supporting small water systems serving under 10,000 people. These rural communities face unique operational, financial, and technical hurdles that larger utilities never encounter. Steve shared insights into these problems and practical solutions that can make a real difference.

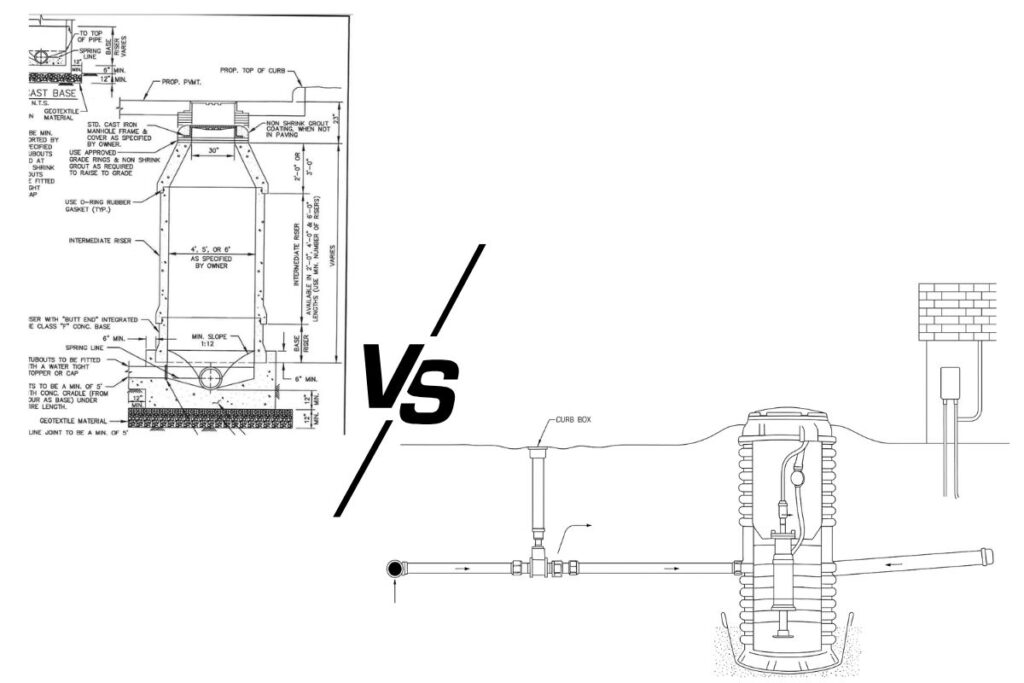

Gravity Sewer vs. Pressure Sewer: Choosing the Right System for Your Community

Planning sewer infrastructure isn’t the most exciting part of development, but getting it wrong can be expensive. The choice between gravity and pressure sewer systems will impact your project for decades, from what you spend upfront to how much maintenance crews will be dealing with down the road.

When Lift Station Force Mains Fail: Your Colorado Community’s CIPP Solution

Force main failures in lift station systems create some of the worst emergencies small communities can face. Unlike gravity sewer problems that develop gradually, pressurized force main breaks happen fast and cause immediate disasters. Raw sewage backs up into pump stations, triggers environmental violations, and can shut down entire wastewater systems within hours.

Why EPANET Is the First Choice for Water Network Modeling

Ever wonder why water pressure stays consistent whether you live downtown or up in the foothills? That reliability comes from careful engineering using specialized computer tools. EPANET modelling software lets engineers test water systems digitally before spending millions on actual pipes and pumps. This EPA-developed program has become the go-to tool for water professionals who need to figure out pipe sizes, predict pressure problems, and track how water quality changes as it travels through miles of underground infrastructure. Small communities and large urban areas both depend on this modeling technology to keep water flowing properly while satisfying state health department requirements.

Fire Flow Analysis: Engineering Solutions for Municipal Water Distribution Systems

Manholes collapsing in your community is one of those infrastructure nightmares that keeps public works directors up at night. When residents see emergency crews digging up streets and sewage backing up into their neighborhoods, they understandably demand answers. The truth is, most manhole failures come from predictable deterioration that we can prevent with the right approach. Understanding these problems helps communities fix them before they become expensive emergencies.

Why Colorado Manholes Fail: Engineering Solutions That Work

Manholes collapsing in your community is one of those infrastructure nightmares that keeps public works directors up at night. When residents see emergency crews digging up streets and sewage backing up into their neighborhoods, they understandably demand answers. The truth is, most manhole failures come from predictable deterioration that we can prevent with the right approach. Understanding these problems helps communities fix them before they become expensive emergencies.

I&I Analysis: Finding and Fixing Your Worst Sections

A practical guide to prioritizing infiltration and inflow repairs for maximum ROI

If you’re managing a wastewater collection system, you already know the drain that infiltration and inflow (I&I) puts on your budget. During wet weather events, clean groundwater and stormwater flood into your sanitary sewers, overwhelming treatment plants and driving up operational costs. But here’s the challenge: with limited budgets and miles of pipe to maintain, how do you identify which sections to fix first?

Why Does My Community Have Brown Water?

Complete guide to wastewater discharge permits in Colorado. Understand CDPHE requirements, avoid violations, and streamline your permit application today

Colorado’s Wastewater Discharge Permit Rules: What Communities Need to Know

Complete guide to wastewater discharge permits in Colorado. Understand CDPHE requirements, avoid violations, and streamline your permit application today

What You Should Know About Rainwater Collection Systems for Texas Communities

Marble Falls, Big Spring, and El Paso have something in common – they stopped treating their water systems like three different problems. One Water means connecting what used to be separate: the drinking water plant, the wastewater plant, and stormwater management all work together now.

How Texas Communities Are Solving Water Shortages with Direct Potable Reuse

Marble Falls, Big Spring, and El Paso have something in common – they stopped treating their water systems like three different problems. One Water means connecting what used to be separate: the drinking water plant, the wastewater plant, and stormwater management all work together now.

Understanding Your Community’s Wastewater Collection System

In today’s world, protecting water resources is more critical than ever. At the heart of this mission are environmental engineers, the professionals who design, implement, and refine systems that manage wastewater safely and sustainably. Their work not only protects public health but also preserves the environment for future generations.

Is 40% Water Loss Draining Your 100 Years Old Pipes

As temperatures drop, frozen pipes and water main breaks become a major threat to utilities. When water freezes inside pipes, it expands, causing pressure build-up, cracks, and catastrophic bursts. The result? Sudden surges of water loss costly emergency repairs, and disruptions to service.

Texas Governor Opens $22.5 Billion Water Fund For Wastewater Developers

Texas wastewater permitting requires developers to obtain TCEQ approval before constructing or operating wastewater treatment facilities. The process involves three main permit types: TPDES (surface water discharge), TLAP (land application), and Chapter 210 (reclaimed water reuse).

Texas Wastewater Permitting Guide For Developer

Texas wastewater permitting requires developers to obtain TCEQ approval before constructing or operating wastewater treatment facilities. The process involves three main permit types: TPDES (surface water discharge), TLAP (land application), and Chapter 210 (reclaimed water reuse).

How We Use Microsoft Apps to Accelerate Your Civil Engineering Project Success

Let’s face it – civil engineering projects are messy. There are dozens of people involved, mountains of paperwork, and strict deadlines that never seem to move. Many engineering firms are finding that Microsoft’s apps can cut through this chaos and make projects run smoother. Here’s how they’re doing it.

Understanding Water System Design Quotes: What You’re Really Paying For

When developers receive proposals for water system design, they’re often confronted with surprisingly wide price variations—sometimes differing by a factor of ten. We recently spoke with a developer who had received quotes ranging from $10,000 to $100,000 for what appeared to be the same scope of work.

Managing Colorado’s Aging Water Infrastructure Using Key Strategies

In communities across America, water infrastructure installed during the Johnson and Nixon administrations continues to serve as the backbone of local water supply systems.

Public Water System Design and Implementation in Texas

Designing a new public water system in Texas requires a careful balance of hydraulic design, regulatory compliance, and construction best practices.

What Is Water and Wastewater Engineering?

In today’s world, protecting water resources is more critical than ever. At the heart of this mission are environmental engineers, the professionals who design, implement, and refine systems that manage wastewater safely and sustainably. Their work not only protects public health but also preserves the environment for future generations.

The Role of Environmental Engineers in the Wastewater

In today’s world, protecting water resources is more critical than ever. At the heart of this mission are environmental engineers, the professionals who design, implement, and refine systems that manage wastewater safely and sustainably. Their work not only protects public health but also preserves the environment for future generations.

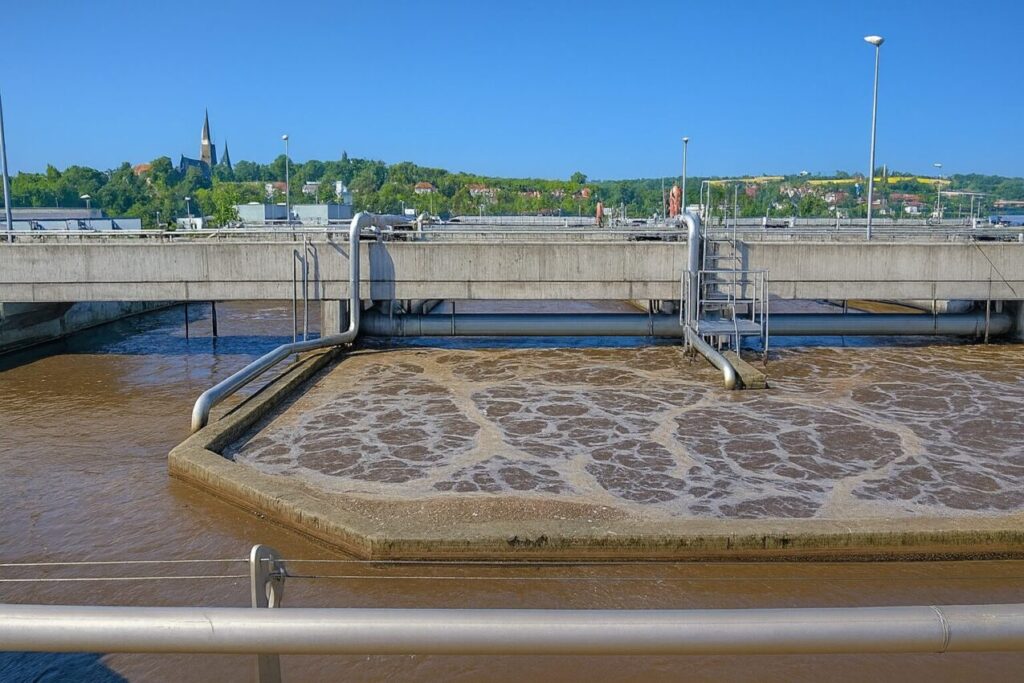

Guide to Design a Wastewater Treatment Plant in AutoCAD

Guide to Design a Wastewater Treatment Plant in AutoCAD Introduction Designing a wastewater treatment plant layout requires both engineering insight and careful CAD drafting. This guide provides a step-by-step approach to creating an AutoCAD wastewater treatment plant design that is accurate, organized, and optimized for collaboration. Tailored as a civil engineering AutoCAD guide for city officials, district managers, professional engineers, municipal planners, and AutoCAD designers, the content focuses on conventional activated sludge systems. We’ll cover everything from initial preparation (gathering site plans and survey data) to detailed layout of treatment units, plus AutoCAD plant design tips on layer management, blocks, Xrefs, and leveraging new software features. If you’ve ever wondered how to draw a wastewater treatment plant in AutoCAD efficiently, read on – this guide will walk you through the process in a professional yet approachable tone. Preparation: Gather Site Plans, Surveys, and Design Specs Before diving into drafting, ensure you have all essential references on hand: Before diving into design, gather your site data and set up AutoCAD for success: Import Accurate Survey Data: Start by attaching the site survey as an external reference (Xref) in AutoCAD. Ensure the drawing uses the correct units (typically feet in Colorado) and coordinate system. Bringing in surveyed points, topographic contours, and property boundaries as a base will ground your design in reality. For example, in Yampa’s project, a detailed survey ensured the new facility fit the site and avoided flood-prone areas. Establish Project Specifications: Set up your drawing template with the project’s layers, text styles, and dimension styles per your standards. Include notes from the project specs (e.g. setback requirements, elevations, discharge point) early on. This preparation helps you adhere to municipal plant AutoCAD design criteria from the beginning. Create Reference Geometry: Draw key reference lines such as property limits, easements, and existing utility locations on separate layers. This makes it easy to see constraints when laying out the treatment units. A well-prepared site plan underlay speeds up the entire wastewater plant layout AutoCAD process by providing context for all design elements. Layer Management and External References (Xrefs) Organizing your drawing with layers and Xrefs is crucial for clarity, especially on complex municipal projects: Use Logical Layer Naming: Separate major categories into layers – e.g., civil site work, structural elements, mechanical piping, electrical, and annotations each on their own layer group. Adopting a consistent naming convention (such as the National CAD Standard) can help differentiate systems. For instance, some designers use a “D” prefix for process design layers (D for “Process”), so layers like D-RAWS-PIPE could denote raw sewage piping and D-RAS-PIPE for return activated sludge lines. Clear layer names ensure anyone reviewing the drawing can instantly distinguish a sludge line from a clean water line. Layer Properties for Clarity: Assign distinct colors or linetypes to different systems – for example, use dashed lines for buried pipes or a specific color for electrical conduits. Keep consistent layer settings (line weights, etc.) so that when the plan is printed, the treatment units and pipes are clearly visible. Layer filters or layer states in AutoCAD can be used to toggle views (e.g., show only civil vs. only mechanical) for easier editing. External References for Collaboration: Break the project into multiple drawings and Xref them together. A common approach is to have a base site plan Xref (with survey and civil features) and separate Xrefs for mechanical process piping or structural details. This way, multiple team members can work in parallel – for example, one drafter updates the site grading while another refines the piping layout. Attach Xrefs as Overlay to prevent nested references from cluttering other drawings. By managing Xrefs and layers carefully, your AutoCAD drawing remains organized even as the design evolves. Don’t forget to periodically purge unused layers and Xrefs to keep the file lightweight and efficient. Layout Tips for Major Treatment Units (Headworks, Aeration, Clarifiers, Sludge Systems) Drafting the major components of a conventional activated sludge plant requires both engineering insight and CAD technique: Headworks Placement: Begin at the plant’s starting point – the headworks (influent screening and grit removal). Position the headworks structure at the incoming sewer location to minimize inlet pipe runs. Allow space for maintenance access (e.g., a driveway for service trucks to remove screenings). In AutoCAD, use concrete pad outlines or equipment blocks to represent the screening unit and any grit chamber. Ensure this area is on a layer for structures and label it clearly (e.g., “Influent Screen”). Aeration Basins: Next, lay out the aeration basin(s) downstream of the headworks. For a conventional activated sludge system, these basins are typically rectangular tanks. Draw the basin walls to scale using actual design dimensions (length, width, and water depth) provided by the process engineer. It’s wise to maintain symmetry and straight flow paths – place aeration basins such that flow can go by gravity to the clarifiers. In the Yampa WWTP design, the aeration basin was oriented to feed two secondary clarifiers by gravity, which simplified piping. Use hatches or fill to distinguish water areas, and consider adding text or a block indicating diffusers or aerators within the basin. Secondary Clarifiers: Position the clarifier(s) immediately after the aeration basin. Often these are circular in plan. Use a circle or polygon of the correct diameter to represent the clarifier tank. If your clarifier is 40 feet in diameter, draw it exactly to scale – precise geometry ensures all piping fits later. Leave room around clarifiers for walkways and sludge pump stations. You might Xref in manufacturer drawings for the clarifier mechanism to get details like center pier or rake arms if needed, or simply represent them with centerlines and a note. Label each clarifier (e.g., “Secondary Clarifier No.1”) and denote the water flow inlet and effluent weir locations on your plan for clarity. Sludge Handling Systems: Include space for sludge processing units. This could be an aerobic digester, sludge holding tank, or dewatering equipment depending on your design. For drafting, place sludge facilities near the clarifiers to shorten sludge piping

Containerized Wastewater Treatment: Modular Solutions for Lagoon Upgrades | WEFTEC SERIES | EP 11

Struggling to meet nitrogen limits? Facing algae outbreaks every discharge season? What if your lagoon could comply without a million-dollar overhaul?

Efficient Pump & Grinder Systems for Small Community Wastewater Needs | WEFTEC SERIES | EP 10

The conversation explores innovative approaches to tackling maintenance challenges, optimizing plant operations, and enhancing support for smaller communities.

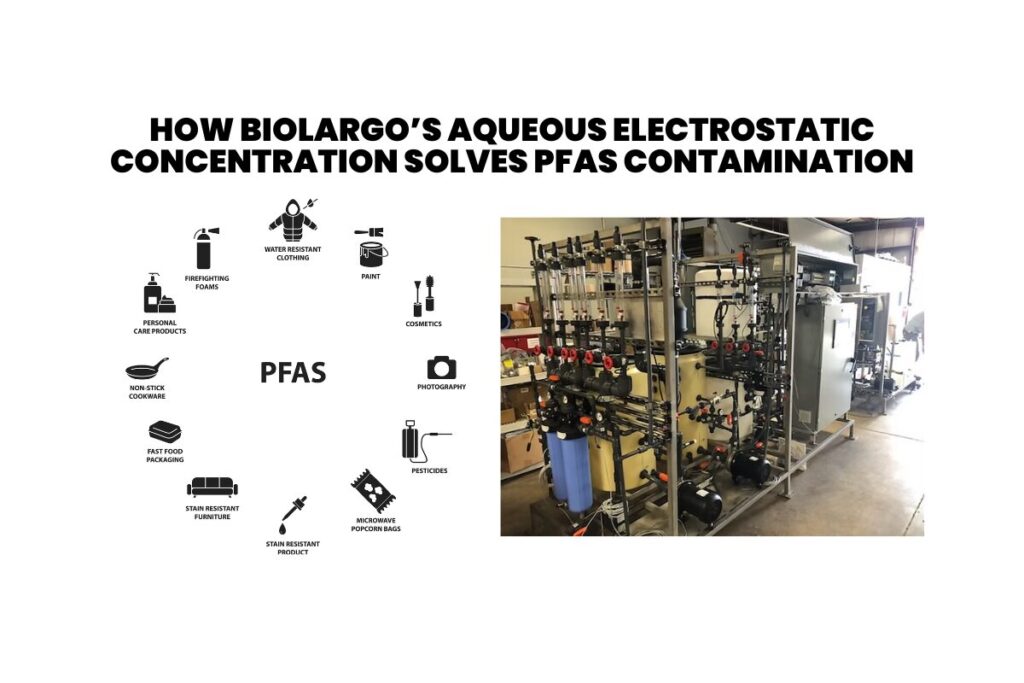

How BioLargo’s Aqueous Electrostatic Concentration Solves PFAS Contamination

In this episode of Engineers for Communities, we spoke with Tanya Chandler and Sally Gutierrez from BioLargo about tackling one of today’s most critical environmental challenges: PFAS contamination. Known as “forever chemicals,” PFAS are widespread in U.S. water systems, posing serious risks to health and the environment. Tanya and Sally shared insights into the issue and groundbreaking solutions that can make a difference.

Are Frozen Mainlines Hurting Your Operation?

As temperatures drop, frozen pipes and water main breaks become a major threat to utilities. When water freezes inside pipes, it expands, causing pressure build-up, cracks, and catastrophic bursts. The result? Sudden surges of water loss costly emergency repairs, and disruptions to service.

Advanced Water Treatment: Chlorination, Flushing & Real-Time Data | WEFTEC SERIES | EP 9

From practical solutions to leveraging advanced data technologies, this conversation offers valuable insights for communities looking to enhance system efficiency and reduce costs.

Simplifying Screening Design & Process | WEFTEC SERIES | EP 8

From practical solutions to leveraging advanced data technologies, this conversation offers valuable insights for communities looking to enhance system efficiency and reduce costs.

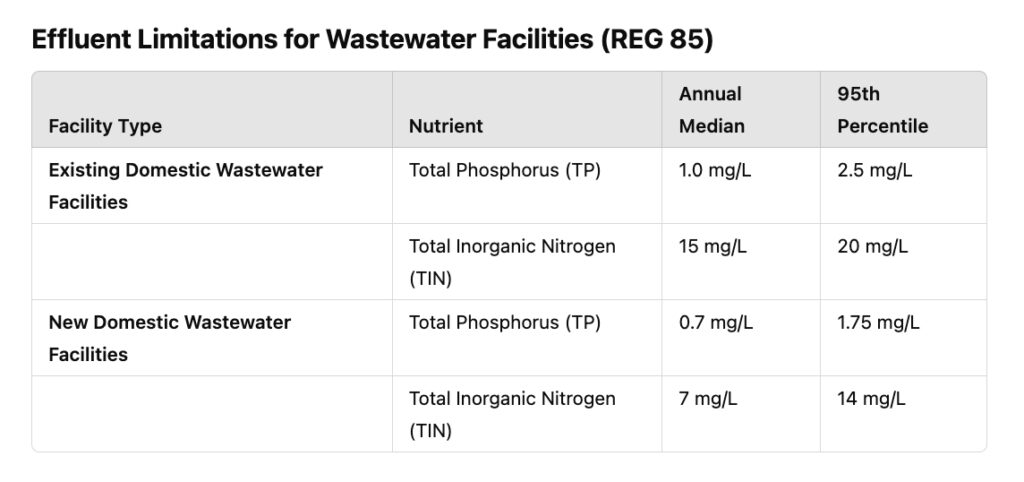

What Colorado Wastewater Providers Need to Know

40% of wastewater plant operators we’ve interviewed struggle to meet effluent quality standards outlined in Colorado’s REG 85. This critical regulation aims to control nutrient levels, including nitrogen and phosphorus, to protect water quality in rivers and streams.

Issues with Your Lagoon Systems? Here’s What You Need to Know

All of the lagoon systems we interviewed had or are currently experiencing issues with meeting effluent requirements. Lagoon systems, which were once considered low-cost and effective, are now facing mounting compliance pressures due to stricter regulations from the Colorado Department of Public Health and Environment (CDPHE).

Tracking and Solving Inflow and Infiltration (I&I) Challenges | WEFTEC SERIES | EP 7

From practical solutions to leveraging advanced data technologies, this conversation offers valuable insights for communities looking to enhance system efficiency and reduce costs.

Energy Solutions for Water and Wastewater Treatment Facilities

Learn how reliable power solutions can safeguard essential services and explore the latest innovations in generator technology.

Future Proofing Wastewater Systems for Rural Communities

Explore how innovative membrane bioreactor (MBR) systems are transforming wastewater treatment for rural communities.

Optimizing Collection Systems: Advanced Solutions for I&I Challenges in Rural Communities

In today’s episode of Engineers for Communities, we delve into a pressing issue facing many rural municipalities: inflow and infiltration (I&I). I’m joined by R.H. Borden, who introduces remarkably simple, yet effective technology designed to tackle I&I challenges efficiently. This device, easily installed in manholes, offers a promising solution to accurately locate and address I&I issues within a matter of feet.

Tracking Water Quality in Real-Time: A Game-Changer for WWTP Operators | WEFTEC SERIES | EP 4

Discover how real-time monitoring technology is revolutionizing water and wastewater management for operators, municipalities, and industrial clients.

Aging Infrastructure and Regulatory Changes in Small Water Systems

These new rules demand significant updates in their operational practices to meet the October 2024 deadline. For smaller water systems, this presents a tough challenge as many lack the necessary resources and data to seamlessly adapt to these requirements.

Upcoming Projects? Learn How to Maximize SRF Funding in 2025

From practical solutions to leveraging advanced data technologies, this conversation offers valuable insights for communities looking to enhance system efficiency and reduce costs.

Wastewater Solutions for Developers and Operators | WEFTEC SERIES | EP 3

This conversation dives into the key considerations developers should focus on when planning wastewater treatment plants and how customizable solutions can optimize efficiency and reduce costs.